Retrofitment

NEW TECHNOLOGIES AND FEATURES FOR EXISTING MACHINES

Through our Retrofits Program, we provide a variety of options to upgrade and update your cutting machine. Parts may be added or replaced to upgrade your machine’s productivity and lifespan.

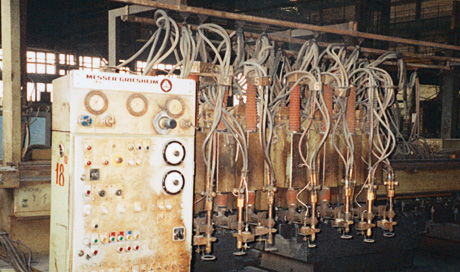

Conversion or retrofits cover the latest technology based on current standards. Replace against modern computer numerical controls or torch suspensions with automatic height control with new process-orientated methods of sensing. Typical components for retrofits are the new generation of power sources for the plasma process or high performance flame cutting torches.

Often it is enough, just to increase the number of torches on the machine thus increasing productivity proportionately. Additional marking processes with powder, plasma or ink simplify the use of the cut parts in subsequent production operations.

This maximizes your productivity by bringing you the latest up to date machine features. We minimize downtime by taking care of as many parts of the retrofit as possible before Service arrives at your location. Conversion and retrofitting gives a new lease of life to cutting systems.

FEATURES:

- Special retrofit packages and parts Rebuilding of complete system

- Upgrades

- Replacement

- Re-manufacturing

- Retrofit of CNC controls, drives, lifters and height control, torches, hoses, cables, bearings, ways, cutting tables and much more

- Complete tear down and build-up

- Comprehensive documentation including schematics

- Pre-assembled prior to shipping for faster installation

- JOBOX including all tools and hardware required for the installation

- High increase in output for little investment

- Short down times

- Better availability of spare parts and consumables