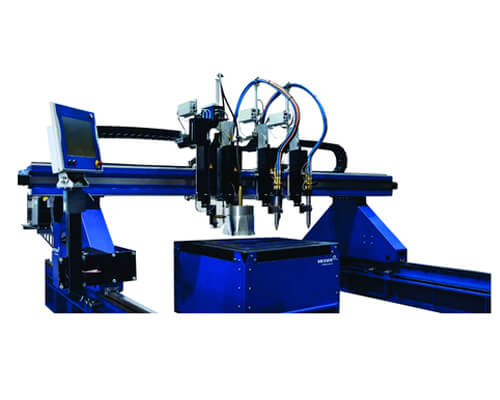

Due to a high level of automation, easy set-up and user friendliness this machine produces quality components – quickly and efficiently. The symmetric wheel-housings and parking space for unused heads optimize the working width but keep space requirements reasonable. The combination of oxyfuel and plasma cutting processes cover all commonly occurring materials and tasks.

KEY FEATURES:

- 100% designed in Messer-Germany for reliability and Quality.

- Increased productivity and flexibility to make it possible to clear the table during cutting.

- Lowest footprint compared to the conventional machine set up.

- Cutting processes: Oxyfuel (Max.) – 300mm (1), Dry Plasma (Max.) – 100mm, Marking Processes: Punch marker, powder marking and single nozzle Ink-jet.

- Positioning speeds of up to 12 m/min.

- Separate cutting table with fume extraction makes it flexible.

- Fast loading and unloading of plates, since the table is accessible from all sides.

- Optional Fast torch lifter (16 m/min) with CNC controlled Z axis for process optimization.

- Working Width up to 5m & Working length up to 38 m.

- Synchronized bilateral longitudinal drives for good acceleration

- Electrical cabinet positioned over the wheel-housing so it is not exposed to thermal radiation